Thiết bị đào tạo hàn Robot | CLASSMATE S | AD2446-5

AD2446-5

Top Features

- WeldPro Software and Training Program

- Integrated safety measures in system and software

- Manual bi-folding door with Shade 10 lens glass for weld viewing

- Curriculum, Train-the-Trainer programs and offline programming software for students available

Processes

MIG/MAG

ADVANCING THE MANUFACTURING SKILLS OF THE NEXT GENERATION

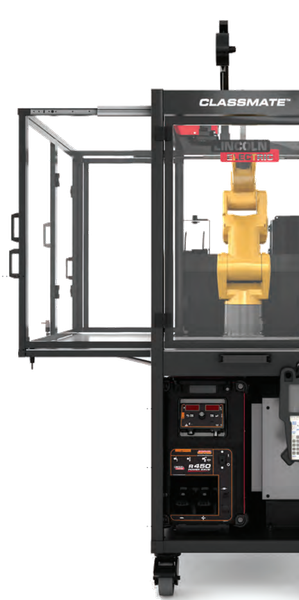

The ClassMate S is designed to help welding educators meet the need for advanced manufacturing training. The robotic welding training system is a preconfigured, self-contained cell constructed for quick and easy installation. The industrial-size robotic welding cell is a single-zone, small footprint system where welders learn to advance their programming and welding skills while replicating a true production environment.

Includes everything you need to present robotic manufacturing

- Exclusive use of FANUC® robots

- Power Wave® R450 power source

- AutoDrive® 4R220 wire feeder

- Magnum® PRO robotic torch

- Integrated safety measures in system and software

- Manual bi-folding door with Shade 10 lens glass for weld viewing

- Pre-Set Custom Lettering Program

- 2 Basic Robotic Programming class seats for instructors

| NET WEIGHT | 2500.00 (1134.00 kg) |

| Robotic System Specifications | |

| PRODUCT NUMBER | AD2446-1 (Basic) |

| WEIGHT | 1000 lb. |

| (H x W x D) - in | 94.23 x 68.23 x 70.24 (sides expanded); 32.5 in. (sides folded) |

| INPUT VOLTAGE | 120V for Robot operation and programming |

| Power Wave® R450 and AutoDrive® 4R100 Product Specifications | |

| PRODUCT NUMBER | Power Wave R450: K3451-1 AutoDrive 4R100: K3002-2 |

| OUTPUT RANGE | 5-550A |

| RATED OUTPUT - CURRENT/VOLTAGE/DUTY CYCLE | GMAW: 550A/41.5V/40% GMAW: 450A/36.5V/100% |

| INPUT VOLTAGE | 208/230/380-415/460/575/3/50/60VAC |

| Robot Specifications | |

| FANUC ARC Mate® 50iD/7L | -Six Axis Mechanical Unit -7 kg Maximum Payload -0.911 m Reach |

| FANUC R-30iB Mate Controller | -6-channel servo amplifier -RIA compliant E-stop unit -Integrated operator panel (includes Auto/T1 mode switch, Estop and cycle start push buttons) -RIA-compliant color haptic iPendant with non touch panel and USB2.0 port |

| FANUC Robotics LR ArcTool® Software | Compliant with RIA R15.06 Safety Requirements |

Đồng bộ gồm có:

Robotic 3-in-1 Welding Fixture – The patent pending 3-in-1 adjustable welding fixture is designed for use on a robotic weld training system. It enables the welding instructor to teach common industry-standard joints and positions, all in one simple device.

Custom Lettering Program – Preprogrammed with easy to use high-quality lettering.

FANUC® fixed headstock robotic positioner - will hold parts up to 1,100 lbs(500 kg)

Robotic Welding Project Based Lesson (K3976-1)

Offer instructors more than a dozen complete project curriculum designed to encourage active inquiry, higher level thinking and easy integration into advanced manufacturing education programs. Includes learning activities, step-by-step instructions and discussion questions.

Basic Robotic Programming Class 3-5 Days for up to 2 instructors WeldPRO® Training (1-seat)

Phụ kiện:

Robotic Education Welding Fixture

Robotic Welding Project Based Lessons - Book 2

RoboGuide® WeldPro® Training & Software – Added Instructor Seat

Robotic Welding Project Based Lessons - Book 1

Video /

Tài liệu

Bridge the Automation Knowledge Gap with ClassMate Education Cells

Today’s manufacturing companies are looking for employees with computer skills, technical training, mathematics and problem-solving abilities. ClassMate® Robotic Welding Trainers

from Lincoln Electric help educators teach up-and-coming welders all those skills and more. Our Robotic Welding Trainers build a strong foundation for these educational programs:

Robotic Welding Training Systems

Put Welders on the Cutting Edge of Automation Technologies

The use of robotic welding systems continues to expand in industrial operations as manufacturers

seek ways to increase productivity amid a shortage of skilled welders in the workforce.

Lincoln Electric robotic welding trainers empower educators to prepare the highly skilled welders needed to operate this in-demand automation equipment.

Why Add a Lincoln Electric Robotic Welding Trainer to Your Welding Program?

1. Provide students with advanced manufacturing skills

2. Utilize current industry technologies, such as the teach pendant, to help welders learn real-world programming skills

3. Increase student participation and engagement with a hands-on training solution.

4. Teach robotics using the equipment implemented in manufacturing and fabrication facilities.

5. Accelerate student skills and capabilities for high graduation employment rates.

6. Pique interest and enrollment in welding with an exciting recruitment tool.

Who Is Using Our Robotic Welding Training Solutions?

High Schools,

Community Colleges,

4-Year Colleges and Universities,

Career & Technical Education Facilities,

Apprenticeship Programs/Labor Unions,

Workforce Development Programs.

We Offer Professional Development & Teaching Assets

In addition to providing instructors the advanced technologies needed to bring hands-on automation training to welders, Lincoln Electric also offers training for welding educators. Our Train-the-Trainer Program includes courses, curriculum and safety materials designed to help instructors magnify their impact in the modern-day classroom.

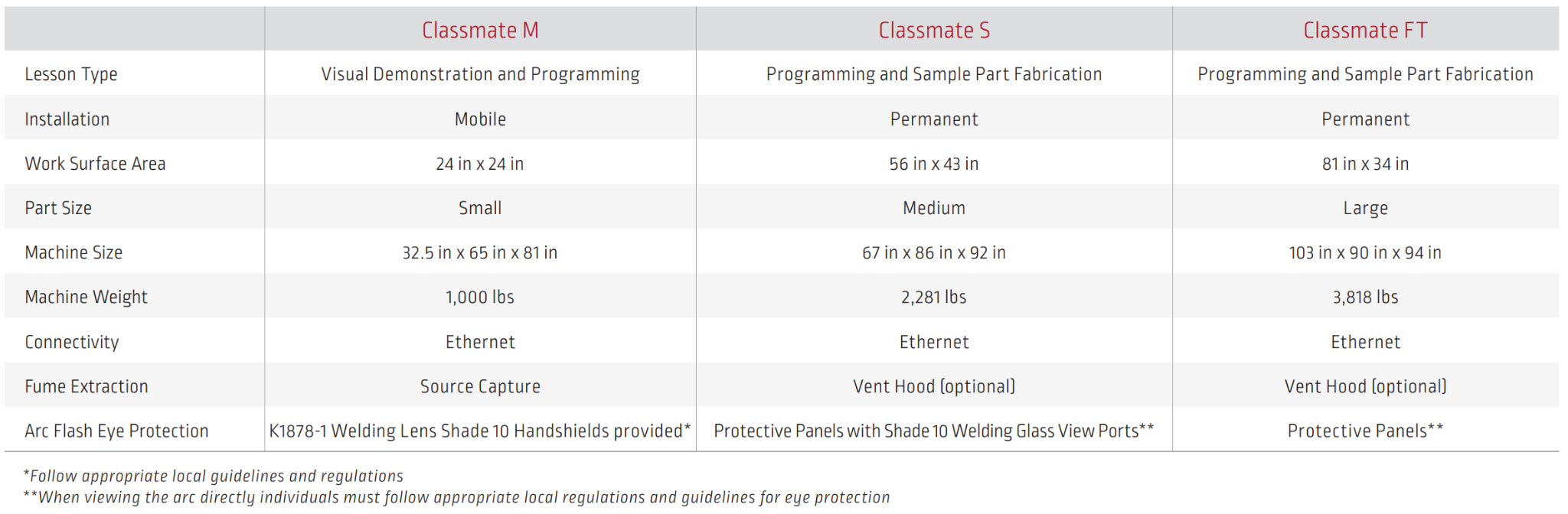

Our Robotic Education Cells Are Designed to Fit Both Space and Curriculum Needs

ClassMate M

Mobile Robotic Cell Easily Moves from Classroom to Lab

- Fits through a standard doorway to teach and practice programming in a classroom and moves to the lab to practice welding

- 3-in-1 adjustable welding fixture enables the welding instructor to teach common industry-standard joints and positions all in one simple device

- Large expandable work surface (2,329 sq in.)

- Easily sets up in seconds

- 3 Packages Available:

° Basic – Standard ClassMate M package

° Intermediate – Includes standard ClassMate M package and WeldPRO® Training Program and Software- Advanced – Includes standard ClassMate M package, WeldPRO Training Program and Software and IRVision® 2D vision camera system.

- Custom Lettering Program is preprogrammed with easy-to-use high-quality lettering

- Includes 2 Basic Robotic Programming class seats for instructors

- Exclusive use of FANUC® robots – the most popular robot manufacturer in the U.S.

- Teach pendant facilitates programming training from hand-held device

- Power Wave® R450 is a full-featured, operational robotic welding power source

- AutoDrive® 4R100 offers powerful wire feeding performance for robotic and hard automation applications

- Includes integrated fume control

- Integrated safety measures in system and software

ClassMate S

Provide Advanced Experience with Larger Components on This Industrial-Level Trainer

- Larger 6-axis Arc Mate™ 100iD FANUC robot is capable of welding medium components with a work area up to 56 in. by 43 in.

- Pre-configured systems – Palletized for easy installation and requires no assembly

- Custom Lettering Program is preprogrammed with easy-to-use high-quality lettering

- Includes 2 Basic Robotic Programming class seats for instructors

- Teach pendant facilitates programming training from hand-held device

- Power Wave R450 is a full-featured, operational robotic welding power source

- AutoDrive 4R220 Robotic wire feeding system offers powerful industry-proven wire feeding performance with the patented MAXTRAC® Wire Drive System

- Integrated safety measures in system and software

- Easy access manual bi-folding door with Shade 10 lens glass for weld viewing

Advanced Training Options:

- Add a fixed headstock robotic positioner for more complicated

welds and programming. Will hold parts up to 500 kg.

Lincoln Electric Robotic ClassMate cells are complete robotic training solutions designed to help welding educators meet the need for advanced manufacturing training. Available in three versions, our line of self-contained robotic welding education equipment covers the spectrum of automation training needs and classroom configurations. Our mobile robotic cell easily transitions from classroom to welding lab, while our industrial-size robotic cells teach students how to weld the larger materials that are commonplace in modern manufacturing fabrication processes. Regardless of size and scale, all versions of the ClassMate robotic cells leverage FANUC robots, and Lincoln Electric’s proven Power Wave and AutoDrive technologies to help up-and-coming welders advance their programming and welding skills.

ClassMate FT

Provide Real-World Experience on Fixed Table Processes with the Largest Components on This Best-in-Class Industrial Solution

- Cell includes fixed table where welders learn to program welds that do not require rotation or repositioning

- Larger 6-axis Arc Mate 100iD FANUC robot is capable of welding large components with a work area up to 81 in. by 34 in.

- Pre-configured systems – Palletized for easy installation and requires no assembly

- Custom Lettering Program is preprogrammed with easy-to-use high-quality lettering

- Includes 2 Basic Robotic Programming class seats for instructors

- Teach pendant facilitates programming training from hand-held device

- Power Wave R450 is a full-featured, operational robotic welding power source

- AutoDrive 4R220 Robotic wire feeding system offers powerful industry-proven wire feeding performance with the patented MAXTRAC® Wire Drive System

- Integrated safety measures in system and software

- Pneumatic front panel ensures staff and student safety during active welding.

Advanced Training Options:

- Add a fixed headstock robotic positioner for more complicated welds and programming. Will hold parts up to 500 kg.

Teach Pendant Provides Advanced Hand-Held Robotic Control

ClassMate Robotic Welding Trainers include a state-of-the-art teach pendant that provides the operator total control of the robot from a hand-held device. The new ClassMate Teach Pendant makes learning how to move and program the robot easier through these advanced features:

• User-friendly 6.4 in. color touchscreen

• Supports HTML 3.2 and JavaScript 1.1 for customization

• Haptic vibration provides tactile feedback to operator

• New intuitive user interface for simplified programming

• Display teach pendant directly to Smart TV for enhanced lab experience

CLASSMATE Comparison Chart

WeldPRO Training Program and Software

Teach Programming and Welding Processes

• Simulate a robotic arc welding process in 3-D space

• Transfer programs from the virtual workcell to an actual robotic cell

• Train multiple students on programming at one time

• Driven by a FANUC Robotics Virtual Robot Controller

• Import actual tooling and workpiece CAD files

• Instructor license includes one seat that does not expire

• Student WeldPRO Simulation Software License Package includes 12-month subscription per student* (25 seats Included)

• Access to Lincoln Electric’s Train-the-Trainer program and ArcTool-based two-day training

* Laptop not included

IRVision 2D Vision Camera System

Improve Weld Quality, Consistency and Repeatability

• Used for joint location tracking, robot guidance and error

proofing prior to establishing an arc

• Improve cycle time and quality